Concrete Carbon Fiber Repair:

A Modern Solution for Structural Integrity

Concrete structures are renowned for their strength and durability, but over time, they can suffer from various forms of damage due to environmental factors, wear and tear, or design flaws. One of the most innovative solutions for restoring and enhancing the structural integrity of concrete is carbon fiber repair.

What is Carbon Fiber Repair?

Carbon fiber repair involves the application of carbon fiber reinforced polymer (CFRP) to existing concrete structures. This advanced material is lightweight yet incredibly strong, offering a high strength-to-weight ratio that makes it an ideal choice for reinforcing and repairing concrete elements.

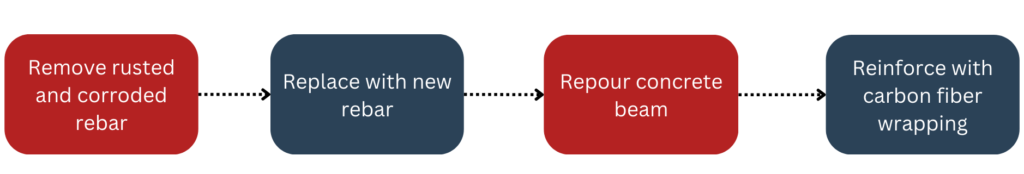

Concrete is vulnerable to damage from the Florida saltwater air, which leads to rebar rusting and corrosion. When rebar rusts, it expands, causing the surrounding concrete to crack and deteriorate (see before photo above). This can result in serious structural failures, as highlighted by the tragic Miami condominium collapse.

This process significantly enhances the concrete’s strength—up to ten times stronger than before. This comprehensive approach will eliminate the chances of structural failure.

Benefits of Carbon Fiber Repair

- Enhanced Strength: Carbon fiber significantly increases the tensile strength of concrete, making it more resistant to cracking and structural failure. This is particularly beneficial for load-bearing applications.

- Lightweight Solution: Unlike traditional repair methods that can add considerable weight to a structure, carbon fiber is lightweight. This means it can be applied without overloading the existing concrete, maintaining the structural balance.

- Corrosion Resistance: Carbon fiber is not susceptible to corrosion, unlike steel reinforcements. This quality extends the lifespan of the repair, making it an excellent option for structures exposed to moisture or aggressive environments.

- Quick Application: The installation process for carbon fiber repair is relatively fast and straightforward. This minimizes downtime, allowing structures to be returned to service more quickly than with traditional repair methods.

- Versatility: Carbon fiber can be applied to a variety of concrete surfaces, including beams, columns, slabs, and walls. Its adaptability makes it suitable for both residential and commercial applications.

The Repair Process

The carbon fiber repair process generally involves the following steps:

- Assessment: A thorough evaluation of the concrete structure is conducted to identify areas of damage and determine the appropriate repair strategy.

- Surface Preparation: The damaged area is cleaned and prepared to ensure optimal adhesion of the carbon fiber. This may include removing loose material and applying a primer.

- Application of Carbon Fiber: Carbon fiber sheets or strips are carefully applied to the prepared surface using an epoxy adhesive. The fibers are aligned strategically to maximize strength.

- Curing: The epoxy is allowed to cure, creating a strong bond between the carbon fiber and the concrete.

- Final Inspection: Once cured, the repaired area is inspected to ensure the integrity of the application and the overall effectiveness of the repair.

Conclusion

We are proud to offer concrete carbon fiber repair as a cutting-edge solution that offers exceptional benefits for enhancing the durability and performance of concrete structures. By utilizing this innovative technology, property owners can effectively address existing damage and extend the lifespan of their assets, all while ensuring safety and structural integrity. Whether for residential renovations or large-scale commercial projects, carbon fiber repair represents a modern approach to concrete restoration that is both efficient and effective.